Home construction from laminated veneer lumber

Houses made of laminated veneer lumber have earned high praise among buyers. Modern material has all the necessary qualities for the construction of housing. Such as safety factor, moisture resistance, durability, resistance to various weather conditions and temperature extremes.

Even at the stage of designing a house, you are faced with the question: choose a ready-made solution or build according to your own measurements?

Finished project: choose from the catalog

We offer many ready-made projects. Сoncluding a contract for the construction of a house from timber according to a finished house project, you get a number of the following advantages:

- lower price, as there are no design costs;

- finished houses have already been made with all nuances of the layout;

- the project of the house is optimized in terms of material consumption, which also affects its price;

- the terms of production and installation of such houses are minimal.

We use latest software in the development of drawings. That is why all our ready-made solutions are so liked with the modern buyer.

But if you want individuality

Planning your dream home, it is not always possible to find something similar on the catalog pages. Our experts will design a house according to your requests. We will help you make your wildest fantasies come true.

It remains only to agree on the project and choose the final stage of construction. We offer the following types of work:

- supply of all necessary materials for self-construction by the customer;

- building a box of house;

- house for rough finishing;

- turnkey glued laminated timber house.

Ready-made sets of houses are made using high-precision equipment. This makes the assembly process much easier. No trimming or making fit required.

Turnkey glued laminated timber house

The cost of a turnkey house is calculated individually for each project. Approximately from 25 thousand rubles per square meter of area. Chose a project to your needs and capabilities.

Only high-quality materials are included in the calculations. We work with trusted suppliers who offer profitable solutions. Thanks to this cooperation, our prices are at an average level with a high quality of finished houses.

Order your dream home

You just need to order a consultation. We will contact you and clarify all details as soon possibile. At the stage of signing the contract, we approve the project and terms construction of a house from timber.

Payment is made in stages. This is more convenient than paying full amount at once. And the final stage of our cooperation is getting a finished house.

Don't delay, make your dreams come true. And we will be happy to help you with this.

Prevention of potential problems at the production stage

| Production of house kits in other companies | Production of house kits in our company |

| Designers «at home» who have little knowledge about features of each material for building a house. | Qualified architects and designers with many years of experience in design of individual residential buildings. |

| Loyal attitude to the quality of wood, the region of growth and the seasonality of felling. If only it is cheaper. | Strict quality control of incoming raw materials. Wood from the northern regions of Russia, mainly from winter felling. |

| Drying planks in natural atmosphere, unbalanced humidity, no intermediate control of the drying process. Due to this there are cracks, warping and wrong geometry of planks. | Automated planks drying process with constant humidity control. Drying of planks to 10-12% moisture. |

| Glued planks are 3-6 meters, that increases the possibility of large cracks and deformation of the timber. | Glued planks into lamellas are trimmed to a length of no more than 1.5 m, that exclude the possibility of cracks and deformation of the timber. |

| Using cheap adhesive systems to the detriment of environmental friendliness, gluing quality and the service life of glued products. | Environmentally friendly adhesive systems of a global concern AKZO NOBEL. |

| Simple cutting of cups without a wind lock increases the possibility of blowing and heat loss in the corners of the house. | A cup of timber with an offset windproof lock, which excludes wind blowing in the corners of the house. |

| Workpieces geometry with large tolerances. | Precise geometry of processed workpieces excludes loose fit of the timber. |

| Cutting parts without optimization increases the waste percentage included in cost of the house. | Thanks to the cutting optimization program, you only pay for the “useful parts” of your house. You do not pay for any waste and cuttings. |

|

Manual drilling of cable ducts during assembly. This increases the assembly time and a margin of error. |

Our machines have the ability to drill cable ducts at the factory. |

| Lack of proper quality control with violations of production technology. If only faster. Unfortunately, you can see flaws in production only on the finished wall or during operation of the house. Fixing or reworking is always more expensive. |

Сonstant quality monitoring at every stage of the production of your future home. Strict adherence to the glued laminated timber production technology.

|

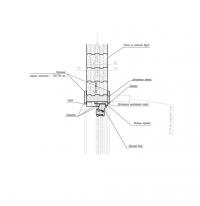

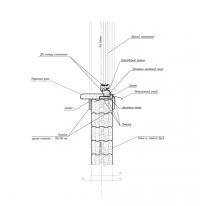

Window installation nodes

|

|

|

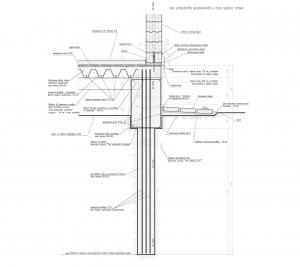

| A node installation of foundations and ground floor | A node roofing with a warm attic |

|

|

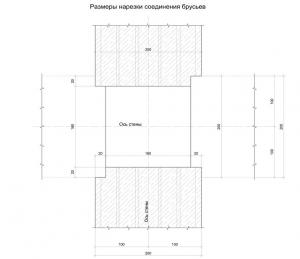

| Section of profiled glued laminated timber | Cutting dimension of joining the timbers |

|

|

Installation of wooden windows in a house made of laminated veneer lumber using a «slider»

|

|

|

|

|

|